4-FACE Fuel Inspection

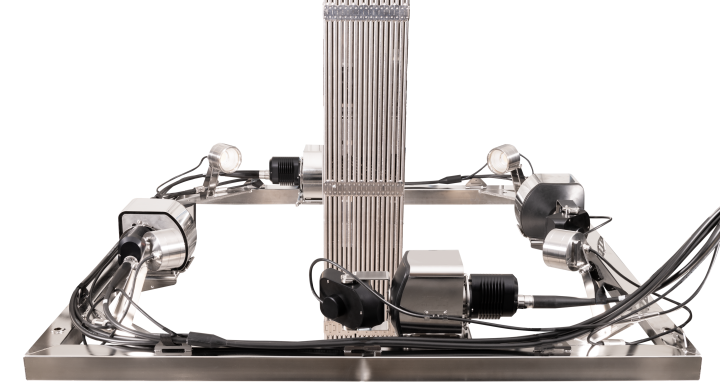

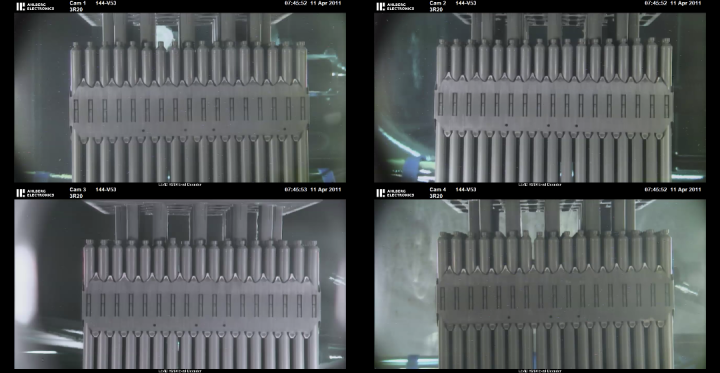

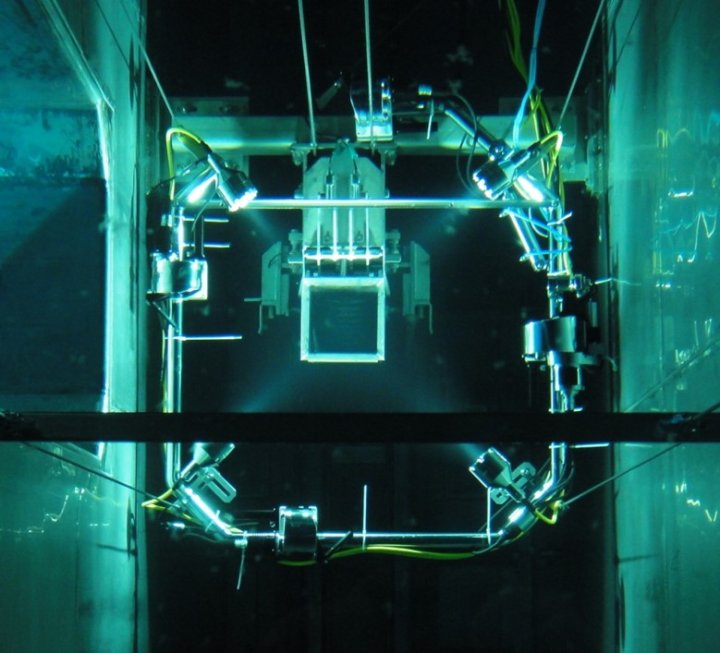

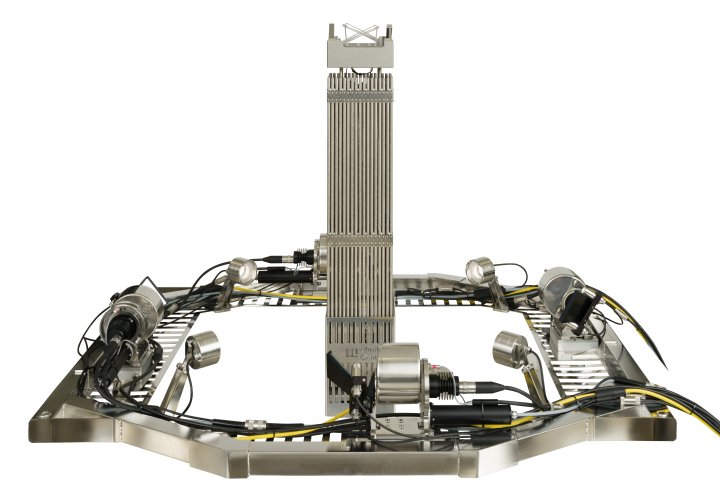

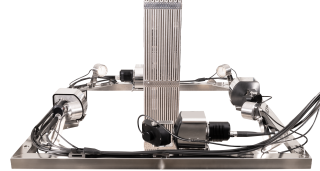

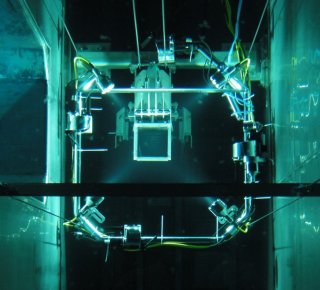

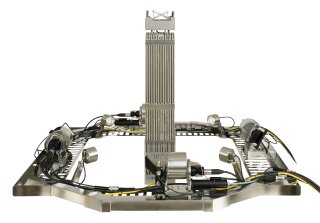

The 4-FACE Fuel Inspection is performed during regular offload in a PWR to find failed fuel. A system of four Full-HD cameras mounted on a frame is e.g. placed above an upender to record a video of all four sides and the bottom nozzle of each fuel assembly passing by. This gives an immediate verification of fuel assembly integrity, without affecting the critical path.

Prefer units:

Technical specifications

-

Physical Characteristics

- Weight of Components

- 400 kg 880 lbs

- Material of Components

- Stainless steel, anodized aluminum

-

Environmental Tolerances

- Operating Temperature

- 70°C 158°F

- Water Tightness

- 3.5 bar 50 psi

-

Camera Rig

- Cameras

- PTZ170

- Lights

- AHL-LIGHT 10

Areas of application

More information about 4-FACE Fuel Inspection

Applications

- Four-side fuel and bottom nozzle inspection during regular offload

- Four-side fuel and bottom nozzle inspection before dry-casque loading

- Additional fuel inspections outside of refueling

Benefits

- Designed for staying underwater for several months

- Fuel assembly bottom nozzle inspection with 5th camera or tilt function in each camera

- Extensive zoom capabilities, x10 optical x10 digital, facilitates finding fuel failures

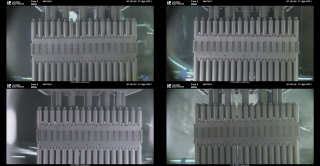

- The monitor display can shift between one-side or quad-side mode, showing either one side of the fuel or all four sides at the same time

Benefits

- Custom built 4-FACE fuel inspection software included featuring video recording, playback of recorded files, slow motion in playback mode, text and audio input in recorded files, panoramic view, and sizing of objects in the images

- Additional software available, e.g. length and bow measurement software for instant calculation of length and bending of fuel assemblies

Benefits

- Possibility to stream video over the utility network

- Customer adapted turnkey system with HW, SW, installation and commissioning, ready for use

- Proven functionality, more than 50 4-FACE systems installed world-wide